How to use a smt underfill epoxy adhesive in various applications

How to use a smt underfill epoxy adhesive in various applications

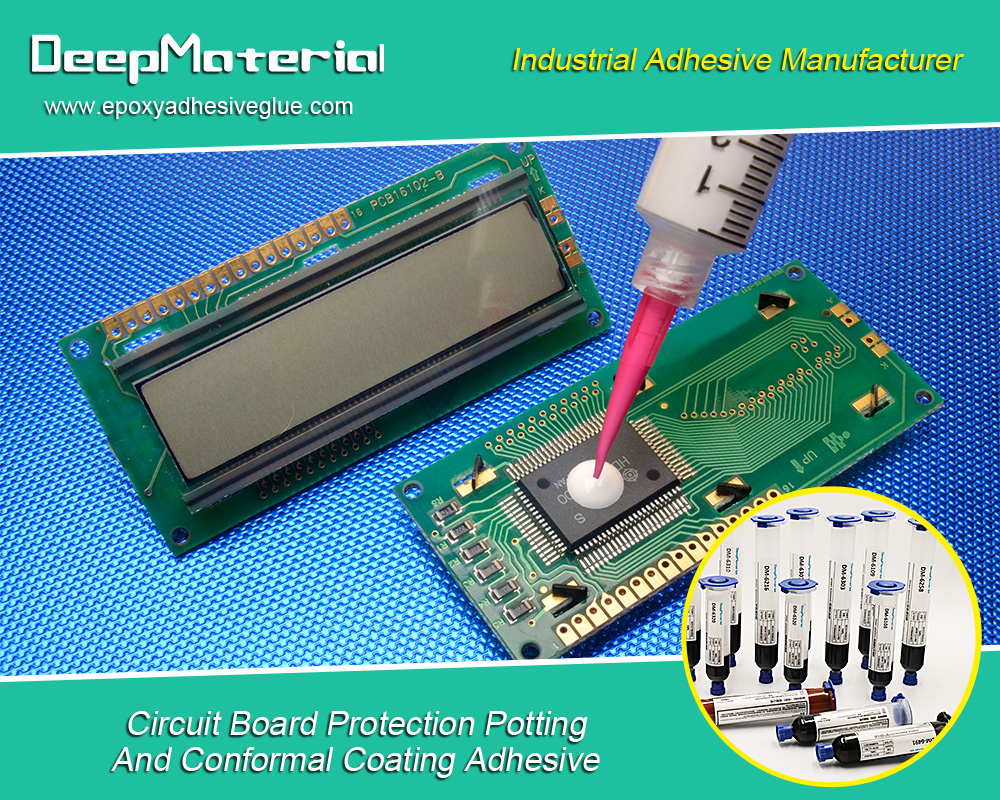

Underfill is a liquid polymer type applied to PCBs after going through a reflow process. After the underfill is placed, it is then allowed to cure, encapsulating the bottom side of a chip covering fragile interconnected pads between the board’s top side and the chip’s bottom side. Underfills offers strong mechanical bonds between the circuit board and chip connection, thus protecting the joints from mechanical stress.

They are also helpful in heat transfer on the same and soften the mismatch in CTE between the board and the chip. The coefficient of thermal expansion (CTE) is the volume or shape change resulting from heat. The underfill epoxy offers much needed protection from such elements.

Adhesive compounds are used in underfill applications to fill the gaps between printed circuit boards and the microchip packages. The filling is necessary because newer chip package types like CSP and BGA are mounted on the surface; solder joints connect the bottom surface of the package to the circuit boards providing the electrical connection.

A while back, DIP dual-inline packages were used, and featured metal leads were inserted into holes on printed circuit boards and soldered. The metal leads offer secure mounts to the circuit boards but left the surface mount prone to breakages of the connecting solder to the printed circuit boards. This was majorly because of mechanical and thermal stresses.

Epoxy underfill

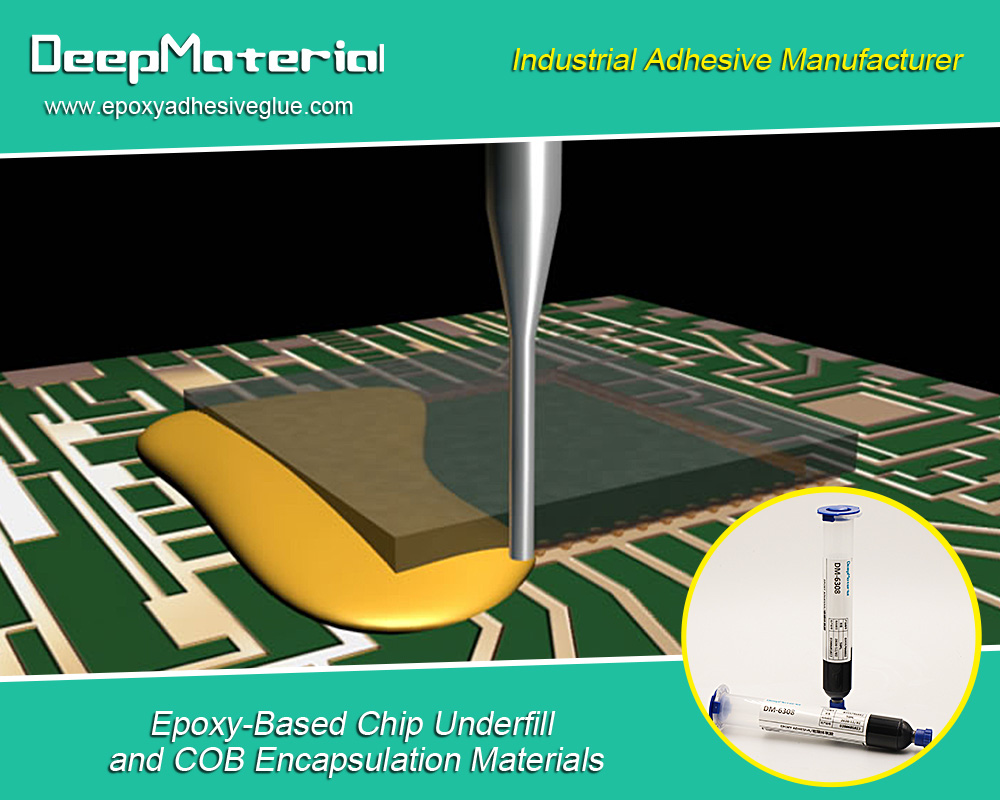

Epoxy remains to be the most preferred adhesive substance used for underfilling. It is mostly because it functions effectively on various applications and has amazing properties to serve desired needs. An epoxy underfill is reliable when used appropriately, and manufacturers know how to handle it to match their packaging requirements.

The epoxy adhesive application is made from one or more edges of the chip package before heat is applied to allow the substance to flow under the chip by capillary action. When underfilling with epoxy, the application methods that can be used include:

Full underfill – which covers all the space between the printed circuit board and the chip package

Edge bonding – which fills a short distance under the chip package edge

Corner staking – which features the application of the epoxy adhesive to the four corners only

The epoxy adhesive makes a good underfill substance because it has important flow properties, which include:

- Low viscosity, which allows the adhesive to flow into tiny spaces as small as 0.1mm

- Low thixotropy, meaning the adhesive viscosity properties remain constant over a period even when it is subjected to shear stress

- Good wetting, which allows the formation of a good bond between the printed circuit board and the chip package

- Anti-foam properties which are ideal in preventing air bubbles in the adhesive once it is cured

A good underfill substance needs mechanical properties like toughness so that it is resistant to drop impacts, a low thermal expansion coefficient, and is resistant to shear stresses. Low moisture absorption and penetration to ensure that the solder connections are safe from corrosion. DeepMaterial is a reliable adhesive manufacturer offering a wide range of quality products to match all your applications. Whether you are looking for epoxy underfill or epoxy potting substance, the company has it all!

For more about how to use a smt underfill epoxy adhesive in various applications,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/best-bga-underfill-epoxy-adhesive-glue-solutions-for-excellent-surface-mount-smt-component-performance/ for more info.