High Refractive Index Epoxy: Properties, Applications, and Advancements

High Refractive Index Epoxy: Properties, Applications, and Advancements

High refractive index epoxy (HRIE) resins, a testament to the constant innovation in materials science, offer unique optical and mechanical properties. These cutting-edge epoxies are revolutionizing various applications, from photonics and optoelectronics to advanced coatings and adhesives. This article delves into the fascinating world of high refractive index epoxies, exploring their fundamental characteristics, synthesis methods, applications, and recent advancements in the field.

Understanding Refractive Index

A material’s refractive index (RI) measures how much it can bend (or refract) light. It is a dimensionless number that describes how light propagates through the material. High-refractive index materials, such as lenses, optical fibers, and coatings, are crucial in applications where light manipulation is essential. The higher the refractive index, the greater the material’s ability to bend light.

Properties of High Refractive Index Epoxy

Optical Properties

- Refractive Index: The most defining property of HRIE is its high refractive index, typically above 1.6. This property makes HRIE suitable for optical devices where minimizing light loss and maximizing efficiency is critical.

- Transparency: HRIE resins often maintain excellent transparency, which is crucial for applications in lenses, displays, and optical coatings.

- Dispersion: HRIE materials can be engineered to have specific dispersive properties, such as the degree to which light is spread out or separated into its component colors.

Mechanical Properties

- Strength and Durability: High refractive index epoxies exhibit excellent mechanical strength and durability. They provide robust protection and support for delicate optical components.

- Adhesion: These epoxies have strong adhesive properties, making them ideal for bonding materials in composite structures.

- Thermal Stability: Many HRIE formulations are designed to withstand high temperatures without degrading, making them suitable for environments with significant thermal variations.

Chemical Properties

- Chemical Resistance: HRIE resins often resist various chemicals essential for maintaining integrity and performance in harsh environments.

- Curing: These epoxies typically cure at room temperature or under mild heat, offering ease of use and versatility in different application scenarios.

Synthesis of High Refractive Index Epoxy

The synthesis of HRIE involves incorporating high-refractive-index components into the epoxy matrix. Common methods include:

Incorporation of Aromatic Compounds

Aromatic compounds, such as benzene rings, significantly increase the refractive index due to their high electron density and polarizability. These compounds are often introduced into the epoxy resin as side chains or incorporated into the backbone structure.

Use of Metal Oxides

Nanoparticles of metal oxides such as titanium dioxide (TiO2) or zirconium dioxide (ZrO2) are dispersed within the epoxy matrix to enhance the refractive index. These metal oxides have intrinsically high refractive indices and, when uniformly dispersed, can significantly improve the overall RI of the composite material.

Introduction of Halogens

Halogenated compounds, particularly those containing bromine or iodine, are sometimes used to increase the refractive index. The heavy halogen atoms contribute to higher electron density, thus boosting the refractive index.

Applications of High Refractive Index Epoxy

Optoelectronics

- LED Encapsulation: HRIE is widely used in the encapsulation of LEDs. The high refractive index helps minimize light loss at the interface between the LED and the encapsulating material, thereby enhancing the efficiency and brightness of the LED.

- Optical Fibers: In optical fiber technology, HRIE is used as a cladding material to maintain the light within the fiber’s core, improving signal strength and transmission efficiency.

Lenses and Optical Components

- Camera Lenses: High refractive index epoxies are employed in camera lenses to achieve better focus and clarity. They help design thin and light lenses without compromising optical performance.

- Eyeglasses: HRIE materials are used in high-quality eyeglass lenses, providing thinner lenses with superior optical properties.

Coatings and Adhesives

- Protective Coatings: These epoxies are used as protective coatings on various surfaces, providing mechanical protection and optical clarity. They are instrumental in displays and solar panels.

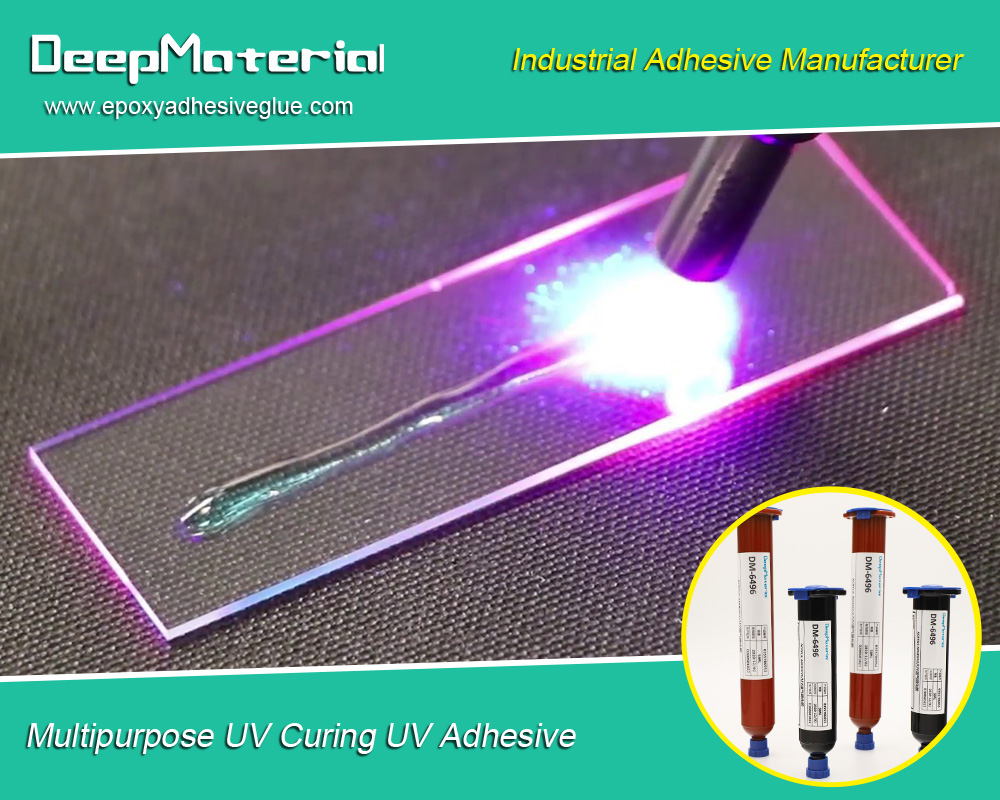

- Adhesives: In electronics, HRIE adhesives bond components without interfering with their optical properties. These adhesives ensure that the components remain securely attached while maintaining the integrity of light transmission.

Photonic Devices

High refractive index epoxies are crucial in fabricating photonic devices such as waveguides and modulators. Their ability to manipulate light makes them ideal for creating high-precision devices that control and direct sunlight.

Advancements in High Refractive Index Epoxy

Nanocomposite Technology

The development of nanocomposite HRIEs involves integrating nanoscale fillers into the epoxy matrix. These fillers, such as nano clays, carbon nanotubes, and metal nanoparticles, enhance the epoxy’s refractive index and mechanical properties. However, the challenge lies in achieving uniform dispersion of these nanoparticles to avoid aggregation, which can negatively affect the material’s properties. Researchers are exploring various techniques, such as surface functionalization and advanced mixing methods, to overcome this challenge and ensure the consistent performance of HRIEs.

Functionalization of Nanoparticles

Surface functionalization techniques are employed to improve the compatibility and dispersion of nanoparticles within the epoxy matrix. By modifying the surface chemistry of nanoparticles, researchers can enhance their interaction with the epoxy matrix, resulting in better dispersion and improved properties. Functionalization can be achieved through chemical treatments that graft functional groups onto the nanoparticle surfaces, promoting better integration within the epoxy resin.

Advanced Polymer Chemistry

Advancements in polymer chemistry have led to the development of new epoxy formulations with higher refractive indices. By carefully designing the molecular structure of the epoxy resin, scientists can tailor the refractive index to meet specific application requirements. It involves incorporating high-RI monomers and oligomers, optimizing cross-linking density, and using advanced curing agents to achieve desired optical and mechanical properties.

Hybrid Organic-Inorganic Systems

Hybrid organic-inorganic high refractive index epoxies combine the best of both worlds. These systems incorporate inorganic materials like metal oxides within an organic epoxy matrix. The synergy between the organic and inorganic components results in materials that offer superior optical, mechanical, and thermal properties. The challenge is to achieve a stable and uniform distribution of the inorganic components within the organic matrix to ensure consistent performance.

Application-Specific Developments

Different applications have unique requirements, and researchers continually develop HRIE formulations tailored to specific needs. For example, in the field of flexible electronics, HRIEs with enhanced flexibility and low-temperature curing capabilities are being developed. Similarly, HRIEs with improved thermal stability and resistance to thermal cycling are being designed for high-temperature applications.

Environmental and Safety Considerations

Eco-Friendly Formulations

As environmental concerns grow, there is a push towards developing eco-friendly high-refractive index epoxies. It involves using renewable raw materials, reducing hazardous chemicals, and improving the recyclability of epoxy materials. Researchers are exploring bio-based epoxy resins derived from natural sources such as plant oils and lignin, which offer a more sustainable alternative to traditional petrochemical-based epoxies.

Health and Safety

High refractive index epoxies in various applications necessitate adherence to strict health and safety guidelines. Proper handling, storage, and disposal of these materials are crucial to prevent exposure to potentially harmful chemicals. Developing low-toxicity formulations and implementing rigorous safety protocols are essential to ensure the safe use of HRIEs in industrial and consumer applications. Furthermore, as environmental concerns grow, there is a push towards developing eco-friendly high-refractive index epoxies. Researchers are exploring bio-based epoxy resins derived from natural sources such as plant oils and lignin, which offer a more sustainable alternative to traditional petrochemical-based epoxies.

Future Prospects

The high refractive index epoxies field is poised for significant growth and innovation. As technology advances, the demand for materials with superior optical and mechanical properties will continue to rise. Critical areas of future research and development include:

- Enhanced Nanocomposites: Continued exploration of nanocomposite technology will lead to HRIEs with even higher refractive indices and improved performance. The focus will be on achieving better dispersion of nanoparticles and exploring new types of nanofillers.

- Innovative Materials: Developing intelligent high refractive index epoxies that respond to environmental stimuli, such as temperature, light, or electric fields, will open up new possibilities in adaptive optics and advanced photonic devices.

- 3D Printing: Integrating HRIEs into 3D printing technologies will enable the fabrication of complex optical components with customized properties. This will revolutionize the production of lenses, waveguides, and other optical devices.

- Sustainable Solutions: Ongoing efforts to create more sustainable and eco-friendly HRIE formulations will reduce the environmental impact of these materials. The focus will be on developing bio-based epoxies and improving recycling processes.

- Integration with Emerging Technologies: High refractive index epoxies will be crucial in emerging technologies such as augmented reality (AR), virtual reality (VR), and advanced sensor systems. The development of HRIEs tailored to these applications will drive innovation and enhance the performance of these cutting-edge technologies.

Conclusion

High refractive index epoxies are vital in advanced materials, offering unparalleled optical and mechanical properties. From optoelectronics and photonics to protective coatings and adhesives, the applications of HRIEs are vast and continually expanding. Advances in synthesis techniques, nanocomposite technology, and polymer chemistry drive the development of new HRIE formulations with enhanced performance and tailored properties. As the demand for high-performance optical materials grows, high-refractive index epoxies will continue to play a crucial role in shaping the future of technology. The ongoing pursuit of eco-friendly and sustainable solutions will ensure these remarkable materials contribute to a more sustainable and innovative future.

For more about choosing the best High Refractive Index Epoxy: Properties, Applications, and Advancements, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.