Unveiling the World of Non-Conductive Epoxy Resin: A Comprehensive Guide to Manufacturers, Applications, and Innovations

Unveiling the World of Non-Conductive Epoxy Resin: A Comprehensive Guide to Manufacturers, Applications, and Innovations

In industrial materials, epoxy resin is a versatile and indispensable substance applied in various fields, from electronics to aerospace. Among its various forms, non-conductive epoxy resin emerges as a crucial variant, playing a pivotal role in ensuring the safety and efficiency of electronic components. This comprehensive guide delves into the world of non-conductive epoxy resin manufacturers, exploring their significance, applications, and the latest innovations shaping the industry.

Understanding Non-Conductive Epoxy Resin:

Epoxy resin, in its conventional form, exhibits excellent adhesive properties and mechanical strength, making it an ideal choice for various bonding and encapsulation applications. However, non-conductive epoxy resin takes precedence in scenarios where electrical insulation is paramount. This specialized formulation ensures that electrical currents are not conducted through the material, safeguarding sensitive electronic components from damage or malfunction.

Non-conductive epoxy resin achieves its insulating properties through careful formulation, typically incorporating additives or fillers that disrupt the flow of electrical current. Common additives include ceramic or silica particles, which effectively insulate the resin matrix, preventing the passage of electricity.

The Significance of Non-Conductive Epoxy Resin Manufacturers:

Manufacturers of non-conductive epoxy resin play a crucial role in enabling advancements across various industries, including electronics, telecommunications, automotive, and more. Their expertise lies in formulating resin blends with optimal electrical insulation properties and ensuring compatibility with different manufacturing processes and environmental conditions.

These manufacturers employ advanced research and development facilities to continually innovate and refine their products, meeting the evolving needs of their customers. From enhancing thermal conductivity to improving adhesion strength, these companies invest significant resources in pushing the boundaries of non-conductive epoxy resin technology.

Applications Across Industries:

The applications of non-conductive epoxy resin are diverse and far-reaching, spanning multiple industries:

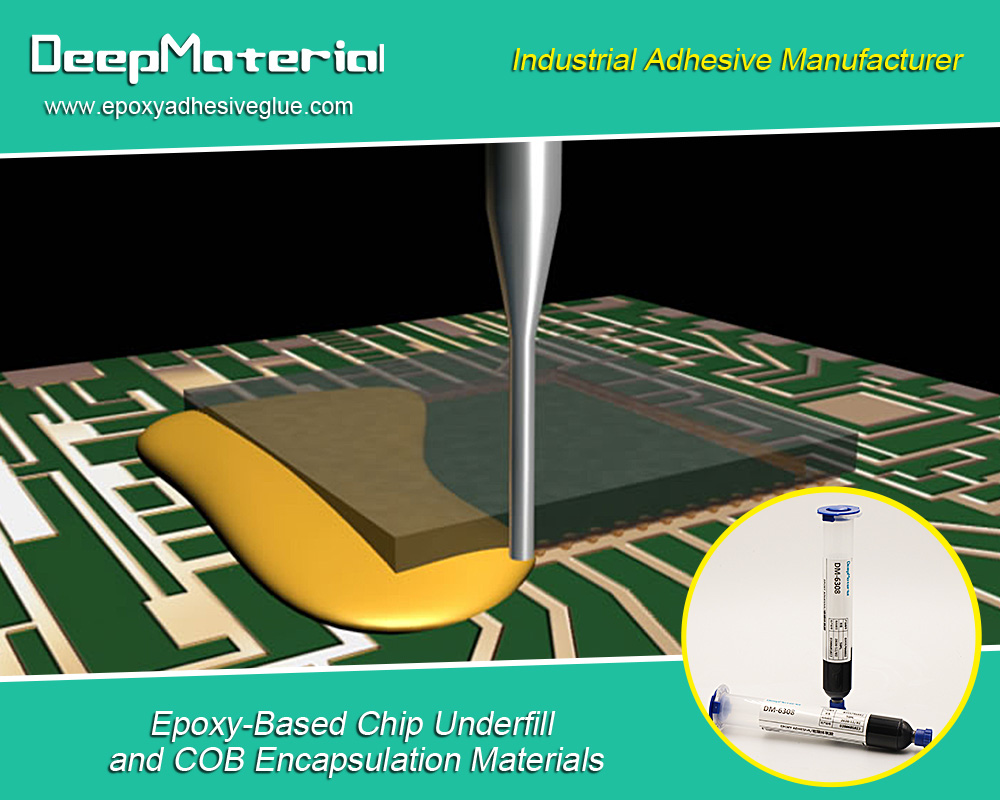

- Electronics:In the electronics industry, non-conductive epoxy resin is extensively used for encapsulating delicate components such as integrated circuits (ICs), printed circuit boards (PCBs), and sensors. Its ability to provide reliable electrical insulation ensures the longevity and performance of electronic devices, even in harsh operating environments.

- Telecommunications:In telecommunications equipment, where signal integrity is paramount, non-conductive epoxy resin encapsulates connectors, antennas, and transmission modules. By preventing electrical interference and signal loss, these resins help maintain the efficiency and reliability of communication networks.

- Automotive:Within the automotive sector, non-conductive epoxy resin plays a critical role in the manufacturing of ignition systems, sensors, and control modules. By safeguarding electronic components from moisture, vibrations, and temperature fluctuations, these resins contribute to modern vehicles’ overall safety and performance.

- Aerospace and Defense:In aerospace and defense applications, where reliability is non-negotiable, non-conductive epoxy resin is used for potting and sealing avionics, radar systems, and missile guidance modules. Its ability to withstand extreme temperatures, high altitudes, and mechanical stress ensures the integrity of critical electronic systems in challenging environments.

Key Innovations Driving the Industry Forward:

The landscape of non-conductive epoxy resin manufacturing is continually evolving, driven by technological advancements and industry demands. Some key innovations shaping the industry include:

- Nanocomposite Formulations:Manufacturers are increasingly leveraging nanotechnology to enhance non-conductive epoxy resin’s electrical and mechanical properties. By incorporating nano-sized fillers such as carbon nanotubes or graphene, these formulations offer superior insulation, thermal conductivity, and mechanical strength compared to traditional resins.

- Low-Cure and Fast-Cure Systems:Manufacturers are developing low-cure and fast-cure epoxy resin systems to meet the growing demand for rapid production cycles. These formulations significantly reduce processing times while maintaining excellent electrical insulation properties, making them ideal for high-volume manufacturing environments.

- Environmental Sustainability:With a growing emphasis on sustainability, manufacturers are exploring eco-friendly alternatives to traditional epoxy resin formulations. Bio-based resins derived from renewable sources such as plant oils or bio-based epoxies are gaining traction, offering comparable performance while reducing environmental impact.

- Intelligent Materials and Additives:Advancements in intelligent materials and additives enable the development of epoxy resin formulations with self-healing capabilities, flame-retardant properties, and enhanced chemical resistance. These innovative additives improve the performance and durability of non-conductive epoxy resin in demanding applications.

Conclusion:

In conclusion, the world of non-conductive epoxy resin manufacturing is characterized by innovation, versatility, and a relentless pursuit of excellence. As electronic systems become increasingly intricate and ubiquitous, the demand for reliable and high-performance insulation materials continues to rise. Manufacturers of non-conductive epoxy resin play a pivotal role in meeting this demand, driving progress across industries and enabling the realization of cutting-edge technologies. With ongoing research and development efforts focused on enhancing performance, sustainability, and efficiency, the future holds promise for further advancements in non-conductive epoxy resin technology.

For more about unveiling the world of non-conductive epoxy resin: a comprehensive guide to manufacturers, applications, and innovations, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.