Clear electronics potting compound and their importance

Clear electronics potting compound and their importance

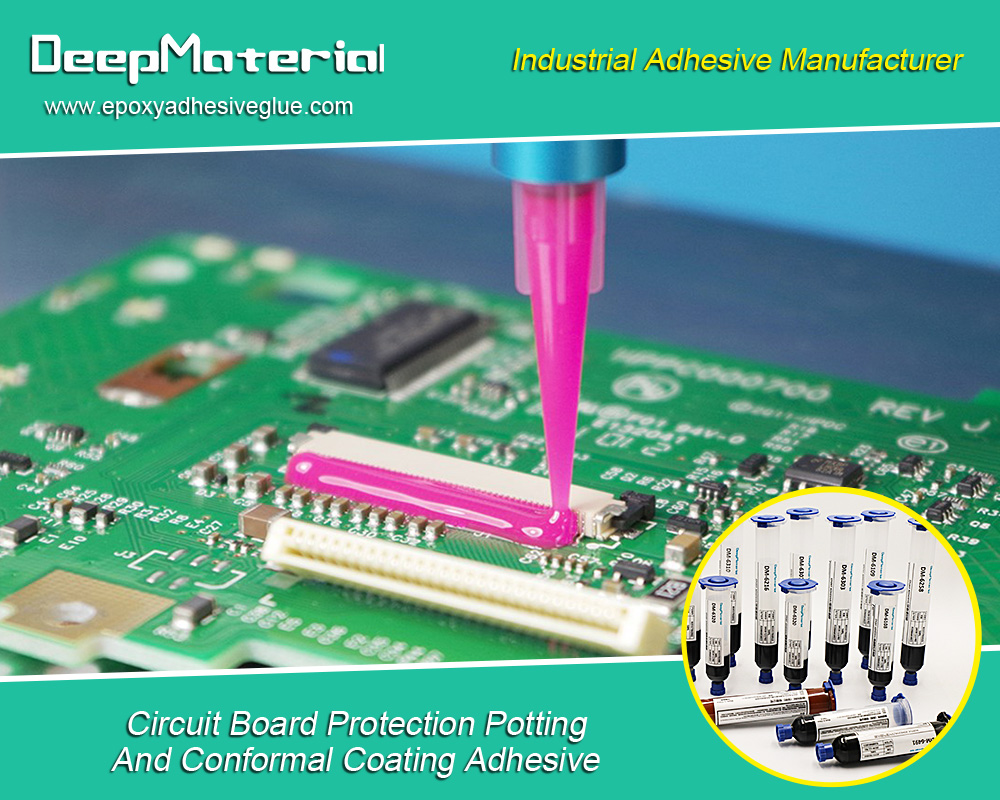

When you want to protect LED and electronic assemblies from the environment, vibration, and shock, encapsulation and potting are the best methods. When you have an application that needs you to see through, it is best to find an optically clear product. This ensures that you can see through the material.

Considerations to make

At times, we cannot hide the circuit. The most common applications for clear electronics potting compounds is where circuitry has LEDs needed for illumination. This covers many things, including torches, traffic lights, and everything.

You may need to use optical potting compounds when electronics have displays or indicator lights, and they have to be seen. There are instances when you need light to get through the material. This is most especially when you have sensors.

All these may be needed, but you still need to ensure the circuitry is protected from the environment. To do it right, you can opt to use enclosures that have clear windows or find a clear resin to pot them.

Protection from environmental factors

It may be necessary to protect your assemblies from chemicals, vibrations, impact, pressure, moisture, debris, and dust. The kind of protection needed from encapsulation or potting should be determined based on the final environment where the product needs to function.

In the case of an underwater swimming pool light, you need something that is entirely waterproof. It should also resist chemicals such as chlorine and others used in such a setting. Lighting indoors doesn’t need much of that water and chemical resistance. It may be necessary for the potting compounds to be scratch resistant and hard if they may be vandalized or walked on.

After environmental assessment, it is important to consider the product sector. If it is the military sector in need of warship lighting, you would need a compound that is reliable, durable, and able to handle ruggedness. There are specific standards for medical devices and other sectors. This is something that has to be determined before a choice is made.

Optical adhesive specification

After determining the protection level that you need, and the assessment has been done successfully, you should now start finding the most appropriate chemistry that will allow you to get the desired clarity and a material that does not yellow. You have to consider the benefits of the process.

For clear potting compounds, there are different chemistries that you can consider. This includes polyurethanes, epoxies, silicones, and UV acrylics. All compounds are great. Each material has its own set of pros and cons. These must be weighed out properly to determine the best option for your needs.

For clarity, you should try polyurethanes. This is because they are UV resistant, they are reasonably priced, and they are versatile. This is to say they can be color-stable without yellowing. After curing, the compounds are very hard and resilient.

The only issue with polyurethanes is their sensitivity to moisture before curing. They need to be completely dry during application and storage.

Best manufacturer

If you want high-quality compounds for your applications, deep material is the best manufacturer to work with. We have been in the market for years now. We are in the best position to supply exactly what is needed for your application. We can custom-make the compounds for you as well.

For more about clear electronics potting compound and their importance,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/pcb-potting-material/ for more info.