All you need to know about Industrial Bonding Adhesives

All you need to know about Industrial Bonding Adhesives

In the assembly of products, adhesives play a critical role in bringing different components together. The use of adhesives for joining various product components has made it possible for different types of consumer goods to be manufactured efficiently.

An Introduction to Adhesives

Industrial bonding adhesives rely on the use of adhesives to join different materials together. Adhesives are chemical compounds that can join two different compounds together. Special adhesives are used in industrial situations to join two or more surfaces together. Industrial adhesives have a higher internal strength than regular glue. The adhesive is used to form the element of connection between the surfaces that are to be joined together. Without the use of adhesives, the surfaces will not be able to stick together. Industrial Adhesives are grouped in various ways. This is by their reaction mechanism, by application, and by chemistry.

Industrial application of adhesives

Adhesive bonding is an industrial joining technique that is applied to repair and assemble a broad selection of products. Adhesive bonding is one of the primary joining processes that is used in industrial applications. The other two joining options are soldering and welding.

Adhesive bonding is based on the use of industrial adhesive to hold one or more materials together. It is a core assembly process for manufacturing different types of products. Many manufacturing processes and markets depend on adhesive bonding to assemble their products. There are numerous types of commercially-available adhesives. This way, different materials can be bonded together to form one product. Industrial bonding Adhesives are widely applied in the production of a diverse range of consumer goods such as medical devices, computers, buildings, personal care products, mobile phones, vehicles, and so on.

Industrial Adhesives are treated chemicals that are meant to join different parts together. The commercially available industrial bonding adhesives include industrial sealants, UV curing adhesives, thermosets, silicone, polyurethane, hot melt, epoxy acrylic, and so on. A majority of industrial adhesives are applied widely in fastening applications.

Types of industrial Adhesives

There are numerous industrial bonding adhesives and they are classified in various ways. You can choose an industrial adhesive by its adhesion properties or by chemical composition. These are the most common types of industrial adhesives:

- UV curing adhesives

- Thermoset adhesives

- Contact adhesives

- Hot melt adhesives

- Rubber adhesives

- Polyurethane adhesives

- Formaldehyde resins

- Epoxy adhesives

- Acrylic adhesives

- Cyanoacrylate adhesives

Properties of industrial adhesives

Fast-setting time: Manufacturing companies choose specific industrial bonds because they cure instantly after application. This helps them to increase their daily throughput by producing more products than usual. The bonds join the materials together the instant that they are applied. This way, manufacturers can quickly assemble a large number of products within a short time. The bonded products can be deployed for use moments after the bonding is completed. Other industrial joining processes like welding and soldering lack this property.

Environmental resistance: Industrial adhesives are applied in products that are meant to resist harsh environmental conditions. This means that they are formulated to resist environmental elements like sustained water, sun, fire, and impact exposure. The high internal strength that the bonds possess makes them sufficiently robust to resist all types of extreme environmental conditions.

Strong bonds: Industrial adhesives are not like regular glues that lack robust bonding properties. Rather than super glues, they have very strong bonds that can last for a long time. They possess strong inner strengths that make them active for years. Industrial bonds are classified as thermoset materials because they can form a strong bond on the application of heat and pressure or only heat. This is why they are used in applications with high load factors.

Industrial bonding adhesives: How to choose the right glue for your product assembly

Due to the wide range of commercially-available industrial adhesives, it is important to understand the right option for your product assembly. TO choose a suitable adhesive, it is important to consider the following parameters:

The stress load: The stress load is an important parameter that you need to consider when choosing the right adhesive. Will you be expecting the bonded material to be subjected to bending, shear, shock, vibration, or permanent load? The adhesive should be sufficient to resist most types of stress loads. It should also have a high tensile strength, which means that it should resist peeling.

Dissolution: If the bond is to be dissolved in the future to retrieve the glued material, then you must choose the right adhesive for this purpose. Various industrial adhesives provide temporary bonds that can be dissolved or taken apart later.

Compliance with standards: Many industries usually have a regulation on accepted adhesives and glues for specific applications. The adhesive you choose for your manufacturing product assembly must comply with the requirements of the regulators.

The working time: The working time of industrial adhesives is something you want to consider. This is the time it takes for you to work the different material surfaces to create a bonded product. In addition, it is important to also consider the time it takes for the adhesive to set fully into position. Most industrial adhesives come with short curing times so that they can be deployed quickly to use. But you also need to check if you will be needing one that has these specific characteristics. Certain industrial glues like cyanoacrylate adhesives can set in a matter of seconds.

Industrial bonding adhesives: A look at the commercial market

The industrial adhesive market features a wide range of glues and adhesives that are formulated to meet a wide range of manufacturing needs. Many manufacturers of adhesives usually have a wide range of products for customers to explore. These adhesive manufacturers have the capability and technology to produce various types of glues based on the requirements of the customers. They also have generic adhesive products that are available in the market as ready-made glues. By specification, each industry needs adhesives with unique specifications because of the nature of the substrate to be glued, the stress load, and their working environments.

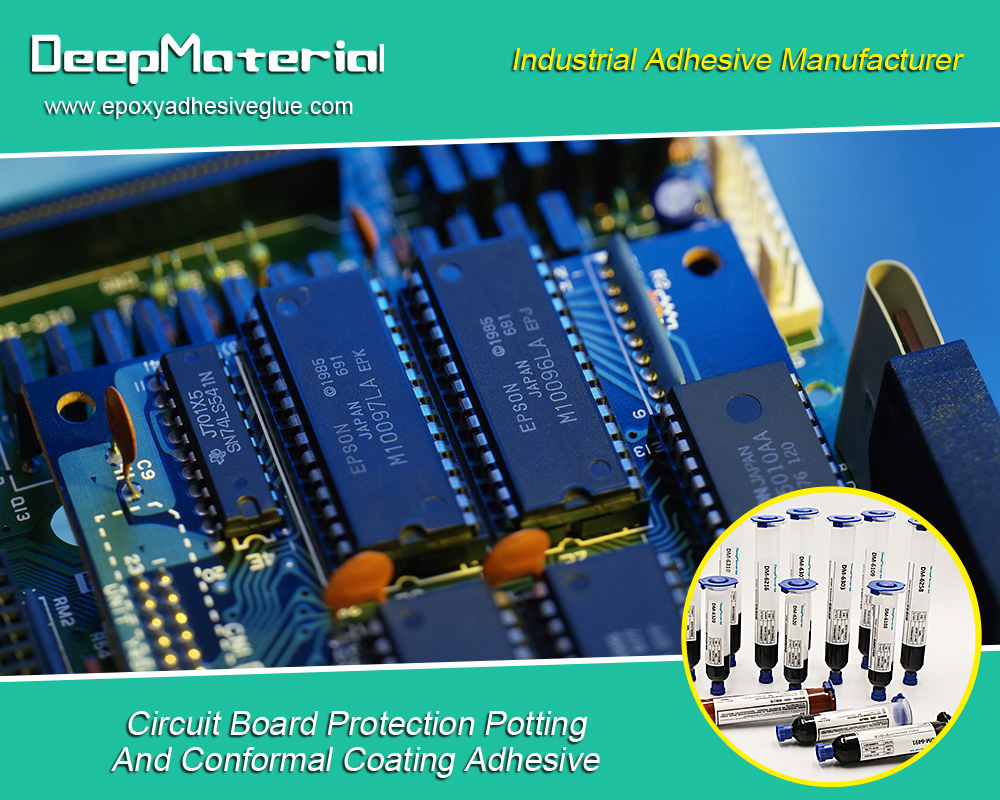

For more about choosing all you need to know about industrial bonding adhesives , you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.