Technical Analysis and Application Exploration of Automatic Fire Extinguishing Materials for Glues

Technical Analysis and Application Exploration of Automatic Fire Extinguishing Materials for Glues

In modern industry and daily life, glue, as an indispensable adhesive material, is widely used in various fields. However, most glues are organic polymer materials, which are flammable. Once a fire occurs, they are extremely likely to fuel the spread of the fire, bringing serious potential safety hazards. Therefore, the development and use of automatic fire extinguishing materials suitable for glues have become a crucial measure to improve fire safety performance. This article will deeply explore the common automatic fire extinguishing materials suitable for glues, analyze their action mechanisms, characteristics, and application scenarios.

Flame Retardants

Flame Retardants

Flame retardants are substances that can enhance the flame resistance of materials, inhibiting the combustion process through physical or chemical actions. In the field of glues, the application of flame retardants can effectively reduce the flammability of glues and decrease the fire risk.

Phosphorus-based Flame Retardants

Phosphorus-based flame retardants have excellent compatibility with glues such as acrylate, which makes them play an important role in the flame retardancy of glues used in adhesive tapes and adhesive cloths for electronic and electrical products. Their action mechanism mainly involves a series of chemical reactions during combustion, ultimately forming a covering layer such as phosphoric acid or polyphosphoric acid. This covering layer is like a automatic fire extinguishing materials suitable for glues, closely isolating the contact between oxygen and the glue. As we know, the three elements of combustion are combustibles, oxygen, and a heat source. By isolating oxygen, the combustion reaction can hardly continue, thus achieving the purpose of inhibiting combustion.

From a microscopic perspective, the phosphoric acid and other substances produced by the thermal decomposition of phosphorus-based flame retardants will promote the carbonization of the glue surface, forming a dense carbon layer. This carbon layer not only has the function of heat insulation but also can prevent the escape of combustible gases, further suppressing combustion. In electronic and electrical products, due to their extremely high requirements for electrical performance, phosphorus-based flame retardants will not significantly affect the electrical insulation performance of the glue while exerting their flame retardant effect, ensuring the normal operation of electronic devices.

Halogen-based Flame Retardants

Halogen-based flame retardants were once widely used due to their extremely high flame retardant efficiency. Their flame retardant principle is to interrupt the chain reaction of combustion by capturing free radicals in the combustion reaction. During the combustion process, free radicals are the key factors maintaining the continuous progress of the combustion reaction. Halogen-based flame retardants can quickly combine with free radicals, making them inactive, and thus the combustion reaction cannot continue to spread.

However, with the continuous improvement of environmental protection awareness, the use of halogen-based flame retardants has gradually been restricted. This is because halogen-based flame retardants will release toxic and harmful gases such as hydrogen halides during combustion, causing serious harm to the environment and human health. Nevertheless, in some industrial glue fields with relatively low environmental protection requirements, such as some building sealants, halogen-based flame retardants are still in use. This is because in these application scenarios, their excellent flame retardant performance and relatively low cost give them certain advantages. But in the long run, finding substitute products for halogen-based flame retardants is an inevitable trend.

Inorganic Flame Retardant Fillers

Inorganic flame retardant fillers such as aluminum hydroxide and magnesium hydroxide will undergo decomposition reactions at high temperatures, and this process is an endothermic process. When the surface temperature of the glue rises due to a fire, the decomposition of inorganic flame retardant fillers absorbs a large amount of heat, effectively reducing the surface temperature of the glue. At the same time, the water vapor generated by the decomposition can dilute the concentration of combustible gases and oxygen.

Taking aluminum hydroxide as an example, its decomposition temperature is between 200 – 300°C. In this temperature range, it will decompose into aluminum oxide and water. The generated water vapor can fill the space around the glue, reducing the concentration of combustible gases and oxygen, making it difficult for the combustion reaction to proceed. Moreover, the aluminum oxide generated after decomposition is a high-temperature resistant substance, which will form a protective film on the surface of the glue, further enhancing the flame retardant performance of the glue. This kind of inorganic flame retardant filler is often used in glues with high requirements for high-temperature performance, such as some industrial high-temperature glues, which can maintain good flame retardant effects in high-temperature environments and ensure the safety of industrial production.

Fire-retardant Additives

Fire-retardant additives are special additives that can improve the fire resistance of glues, enhancing the protection ability of glues in case of a fire through different action methods.

Intumescent Fire-retardant Additives

Intumescent fire-retardant additives will expand at high temperatures in case of a fire, forming a porous carbonaceous layer. This process is like building a solid fireproof wall for the glue, playing the roles of heat insulation and oxygen isolation, and preventing the spread of the fire. Intumescent fire-retardant additives are widely used in building glues and furniture glues.

When a fire occurs and the temperature rises, the intumescent fire-retardant additives start to expand. They will rapidly expand several times or even dozens of times, forming a thick porous carbonaceous layer. This carbonaceous layer has an extremely low thermal conductivity, which can effectively prevent the transfer of heat to the inside of the glue, reducing the temperature of the glue and making it difficult to reach the ignition point. At the same time, the porous structure can adsorb a large amount of combustible gases, reducing the contact opportunity between combustible gases and oxygen, and further inhibiting combustion. For example, after adding intumescent fire-retardant additives to the glues used in the interior decoration of buildings, it can effectively delay the spread of the fire in the initial stage of the fire, buying precious time for personnel evacuation and fire rescue.

Nano Flame Retardant Additives

Nano flame retardant additives such as nano montmorillonite, with their unique nano-size effect and excellent properties, show great potential in the field of glue flame retardancy. Nano montmorillonite is a layered silicate mineral with an extremely high specific surface area and good barrier properties. When added to the glue in a small amount, nano montmorillonite can be uniformly dispersed in the glue matrix, forming a nanoscale network structure.

This nanoscale network structure can not only improve the thermal stability of the glue but also enhance its barrier properties. In terms of thermal stability, nano montmorillonite can restrict the thermal movement of glue molecules and increase the decomposition temperature of the glue. In terms of barrier properties, the lamellar structure of nano montmorillonite can block the diffusion of combustible gases and oxygen, making it difficult for the combustion reaction to proceed. Moreover, due to the small addition amount, nano flame retardant additives have little impact on other properties of the glue and can be used in various types of glues, especially some electronic glues with high performance requirements. In the manufacturing of electronic devices, using glues added with nano flame retardant additives can not only ensure the adhesive performance and electrical performance of the glue but also improve its fire resistance, meeting the requirements of electronic devices for safety and high performance.

Fireproof Sealants

Fireproof sealants are special glues. In addition to having the adhesive properties of ordinary glues, they also have good fire resistance and can form an effective fireproof barrier in case of a fire.

Silicone Fireproof Sealants

Silicone fireproof sealants have many excellent properties, making them one of the preferred materials in the field of fireproof sealing. Firstly, it has good weather resistance and can maintain stable performance under various harsh environmental conditions and is not easy to age. Whether it is high temperature, low temperature, or ultraviolet radiation, it will not have a significant impact on its performance. Secondly, silicone fireproof sealants have excellent high and low temperature resistance and can work normally in the temperature range of – 50°C to 200°C.

When a fire occurs, silicone fireproof sealants can quickly form an effective fireproof sealing layer. It has good adhesive properties and can closely fill parts such as building joints and pipe penetration points, preventing the spread of fire and smoke. In the construction field, silicone fireproof sealants are widely used for the sealing of building joints, such as the joints between floors and walls, and the joints between doors, windows, and walls. In the field of electronic devices, it can be used for the sealing and bonding of the casings of electronic devices with high fire resistance requirements, ensuring the safety of electronic devices in case of a fire, preventing flames and smoke from entering the interior of the devices and damaging the electronic components.

Acrylic Fireproof Sealants

Acrylic fireproof sealants are characterized by their fast curing speed and high adhesive strength. In the fireproof sealing of building doors, windows, curtain walls, etc., the fast curing characteristic greatly improves the construction efficiency and can form an effective fireproof sealing layer in a short time. At the same time, its high adhesive strength can ensure that the sealant is closely combined with the base material and is not easy to fall off.

Acrylic fireproof sealants have good fire resistance. In case of a fire, it can withstand the action of high temperature for a certain period of time and prevent flames and harmful gases from spreading through the joints. In the sealing and bonding of industrial equipment, acrylic fireproof sealants also play an important role. For example, in the fields of chemical equipment, power equipment, etc., using acrylic fireproof sealants to seal the joints of the equipment can effectively prevent the leakage of flames and harmful gases in case of a fire and ensure the safety of industrial production.

There are a wide variety of automatic fire extinguishing materials suitable for glues, and each material has its unique action mechanism, performance characteristics, and application scenarios. With the continuous progress of science and technology and the increasing requirements for fire safety, the future research on automatic fire extinguishing materials for glues will develop towards a more environmentally friendly, efficient, and multifunctional direction. Developing new types of flame retardants, fire-retardant additives, and fireproof sealants, improving the fire resistance of glues, and reducing the fire risk will be an important task to ensure people’s lives and property safety and promote the sustainable development of various industries. We need to keep exploring and innovating, give full play to the advantages of various automatic fire extinguishing materials, and make contributions to building a safe and reliable living and working environment.

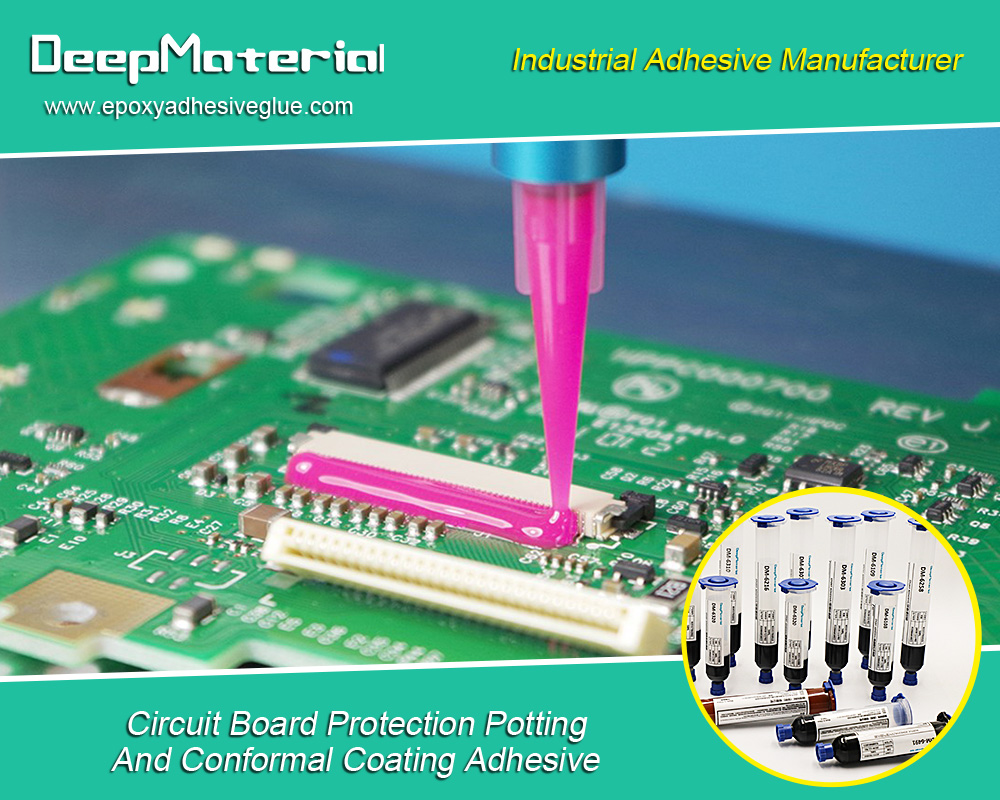

For more about choosing the best technical analysis and application exploration of automatic fire extinguishing materials for glues, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.